Nutcrackers

Entrepreneurs have invented useful tools for cracking nuts. We offer these exceptional inventions here.

The Duke black walnut cracker with the rack and lever action multiplies the force for cracking hard shelled nuts like black walnuts, shellbark hickory and butternuts. The rack allows for some leeway in the nut size being cracked. The anvils screw in an out to accommodate greater or smaller nut size differences. It comes complete with a wood base attached.

The Duke pecan cracker is designed for smaller nuts like pecans and hazelnuts. It is a handy inexpensive tool. It cannot crack black walnuts or hickory nuts.

The V5 Nutcracker – is made from 304 food grade stainless steel. This heirloom is the ‘Cadillac’ of hand nutcrackers, a precision tool for extracting meats from the hardest shelled nuts. It can be 'transformed' to various setups that can be made to suit the nut being cracked.

Watch the You Tube video to see how it can be adapted to suit your needs.

We will forward your order to the manufacturer to whom payment will be made including shipping, helping to save you added costs.

This is our basic hand crank or drill cracker. It is easily converted from a hand crank machine to a drill cracker. It is the best machine of its type on the market. It is suited for cracking thin shelled nuts like hazelnuts, almonds, and Persian walnuts. It will work best if the nuts are sized first but this is not necessary. It is easily adjusted by moving the plate in or out against the cracking roller. Try a few nuts and adjust as needed to get the best crackout. Electric drill is not included.

US customers, please ask for a quote in US funds.

After ordering, please allow up to 2 days for a shipping quote.

To crack hazelnuts by machine, you should size the nuts first. Nuts that are not sized ahead will leave you with 3 results. 1) perfectly cracked nuts, 2) small nuts that fell through the cracker uncracked and, 3) nuts that cracked and split the kernel too.

The uncracked nuts then need to be picked out and put through the cracker with a narrower setting. Cracked kernels also need to be picked out to make a more uniform product. Cracked kernels can mold if left for long in a warm condition.

We invented this simple Canadian made sizing unit that will solve these issues. It has 3 sections, spaced at different intervals. Trays can be used under each section to catch the nuts that fall between the spacing bars. It is operated by pouring a liter or more of nuts at the narrowest spaced bars, spacing them out, and directing the nuts to the next set of bars by pushing or brushing them along. Oversize nuts will fall off the end into a fourth tray.

Catching trays are not included. We suggest using appropriate size plastic bins available at hardware stores.

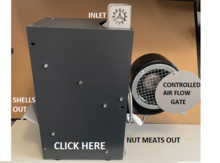

Air Separator

The separator, made in Turkey, will blow out the shell on one side and let the clean nut meats drop out on the other. It works well with all the nuts that have relatively thin, or light shells including hazelnuts, Persian walnuts, acorns, and pecans. Thick shelled nuts like black walnut, butternut and hickory do not separate easily since the shell pieces are heavy so air separation will not work.

It plugs in to a normal 110V outlet. The fan motor is baffled to adjust the air flow.

US customers, please ask for a quote in US funds.

After ordering, please allow up to 2 days for a shipping quote.

The ‘Adjustable Patriot 600’ is designed for commercial and semi-commercial production. It is suitable for cracking any hard shelled nut including black walnuts, shellbark hickory nuts, and butternuts. No need to size the nuts before cracking. As the nuts drop in the narrowing steel hard faced cone shaped chamber, the inner rotating cone spins the nut and shatters it, releasing large meat pieces. The cone spacing can be adjusted from 1/8" to 1 1/2" to crack all nuts from black walnuts to smaller nuts like hazelnuts. This heavily built machine can crack 600 pounds of black walnuts per hour. The steel surfaces are coated with a baked on food grade finish. The sealed 1 hp gear reduction motor operates on 220v power supply. Mounted on 4 heavy duty casters, it can be easily moved. Other than 3 bearings that require occasional greasing, the machine is maintenance free for long term use.

American customers:

Adjustable Patriot 600: $15,500 USD + Shipping. Inquire.